Process-3rd Stage

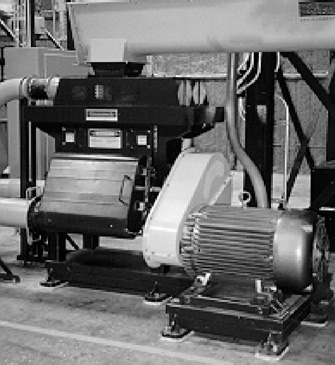

3rd Stage -Reduction to Granules

The minus 5/8」 chips are then fed to a walking-floor chip bin for storage. The chips are then fed to the G3 granulator via a variable speed feed screw. The G3 has several options as to screen size, such as 1/4」, 5/16」 and 3/8」. The G3 then reduces the chips to a minus 1/4」 product size. The material is removed from the G3 via vacuum pneumatics, which also serves to cool the granulator during operation. This phase of reduction provides liberation of a high percentage of fiber, as well as liberating virtually all remaining steel. Metal separation and fiber aspiration follow the G3. Material is then screened and oversized material is recirculated back to the G3 via pneumatics. Minus 1/4」 material that is virtually wire-free, is then conveyed into the powderizer-infeed storage bin or sent directly to the bagging area for packaging to go to end markets. Material at this stage can be marketed for numerous applications, including but not limited to: soil amendment, play ground material road sub-base, and some molded products applications.

G3 video

G3 video