Process-2nd Stage

2nd Stage-Reduction to Chips

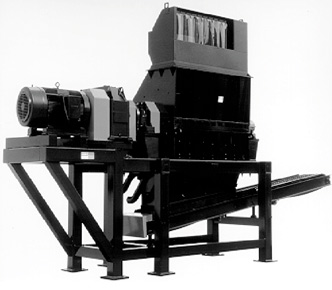

Primary shreds are then fed to the Granutech Model 80 Grizzly. This unit is a single-shaft, intermediate speed device that utilizes an internal screen to retain material in the machine until reduced to a specific size. A number of sizing screen sizes are available. In a crumb rubber system, the primary shreds are reduced to a minus 5/8」 material in the Grizzly. This reduction will allow ferrous metal from the bead and tread area to be liberated, and then magnetically separated, via a cross-belt magnet prior to further processing. This will provide a material that is up to 98% metal-free for ease of further processing. An aspiration system evacuates airborne particulate produced from dust and fiber which is then contained in a filter bag house. Material at this stage can be marketed as high quality wire-free tire derived

Bagger

Bagger